Custom Metal Fabrication

With 2D laser cutting, precision press brake capabilities, deep draw stamping expertise, and more, ATACO has the manufacturing capabilities to produce practically any precision component you need.

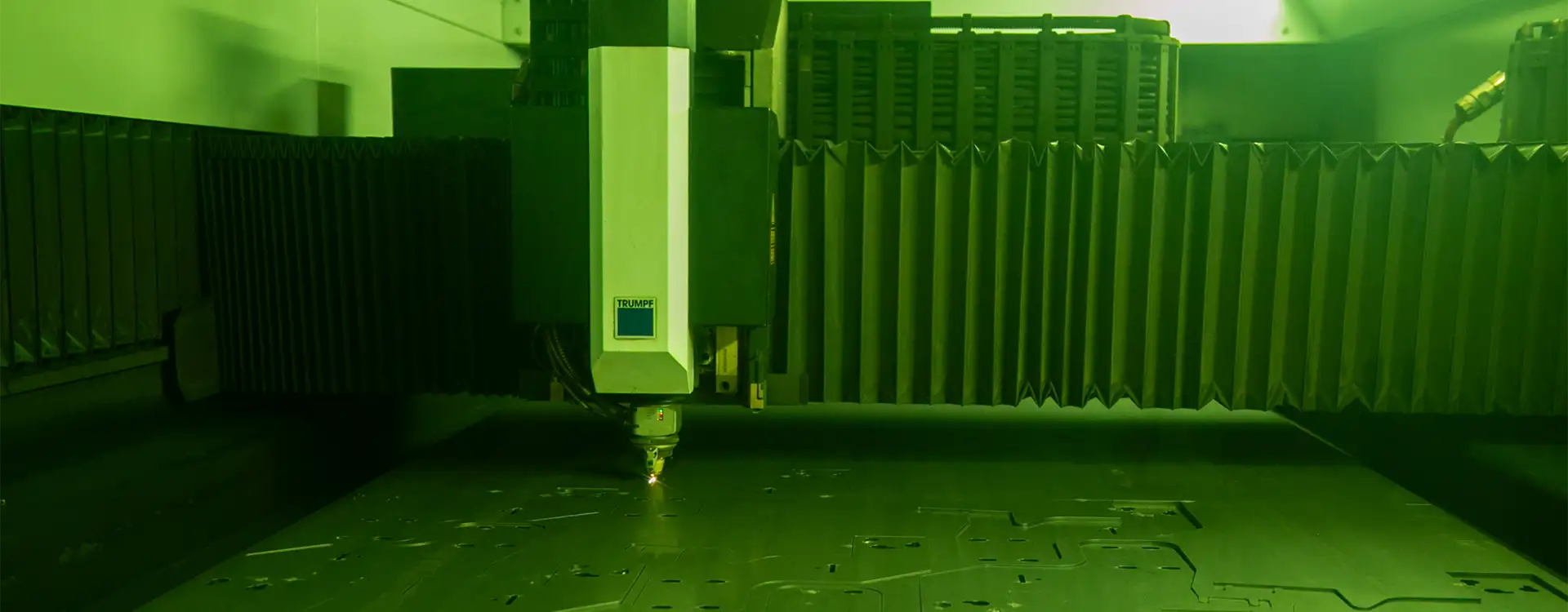

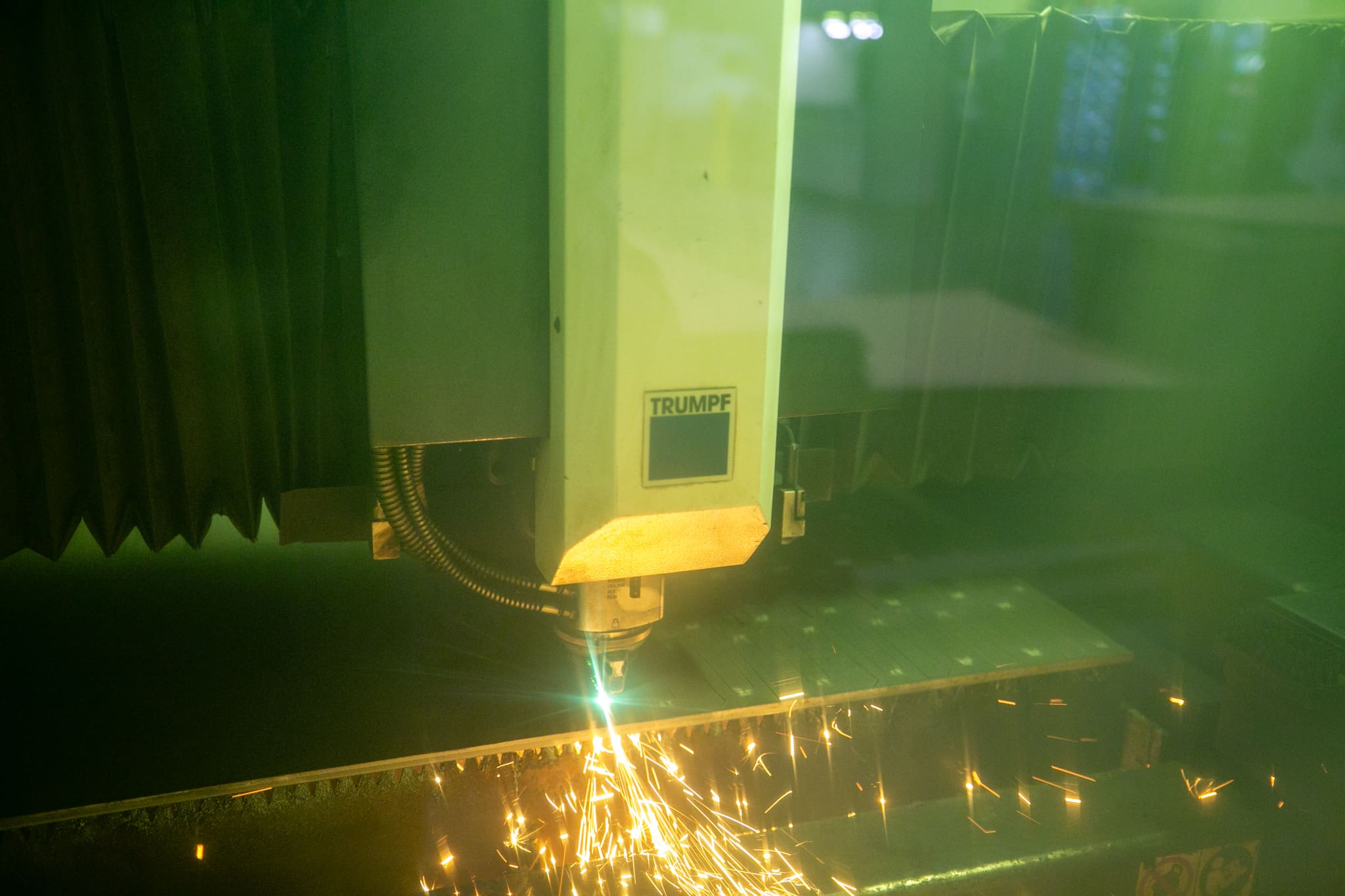

Precision Metal Press Fabrication 2D Laser Cutting

Our press brake expertise enables us to bend, form, and punch sheet metal with outstanding precision. Our press brake equipment utilizes advanced computer software that allows us to draw parts and simulate the forming process before fabrication, eliminating operator guesswork, providing for timelier, more accurate estimates, and ensuring that your deep drawn shells and other stamped metal parts are formed correctly.

We provide 2-D flat laser cutting to cut complex metal shapes and 3D 5-axis laser cutting to cut sheet metal fabrications and metal stamping parts after they are produced. Utilizing advanced cutting technology minimizes the need for expensive, specialized tooling, which significantly reduces overall production costs. This can replace many drilling, milling, and manual cutting operations for faster, more cost-effective, and more accurate fabrication.

Servo-driven hydraulic systems enable us to hold extremely tight tolerances and match your specifications exactly, even in the most challenging steel fabrication applications. Our hydraulic clamping and sectionalized tooling further decrease set-up times and eliminate the expense of custom-purchased tooling.

Wisconsin Stamping & Manufacturing

Located near Milwaukee, we offer custom metal fabrication to our customers throughout Wisconsin and nationwide.

Request a quote today for your custom metal fabrication project, or contact ATACO Steel Products for more information.