In-House Metallographic Testing for Certified Weld Quality

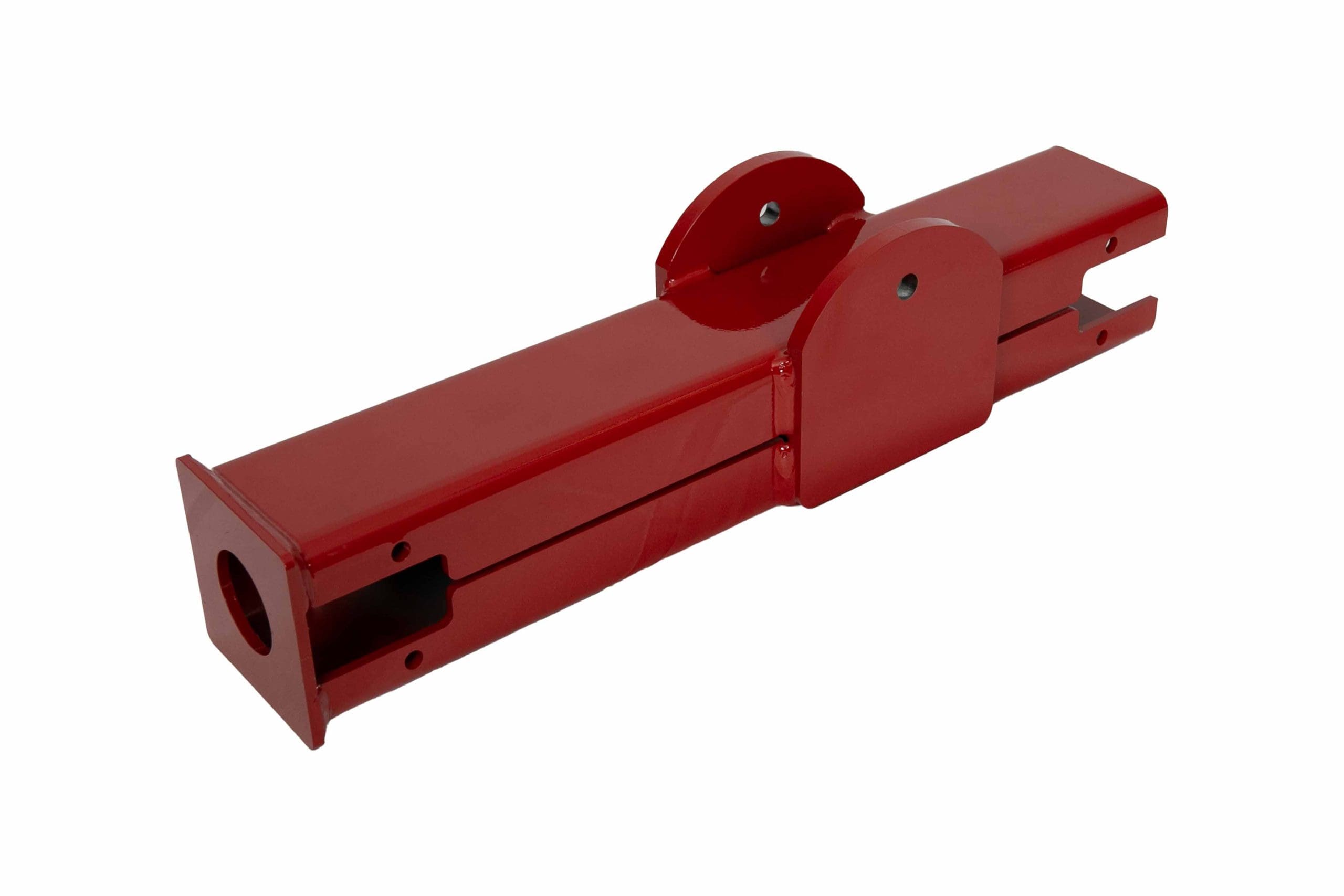

ATACO Steel Products’ in-house Cut & Etch Lab provides fast, precise weld verification for critical parts across construction, agriculture, and material handling industries.

Macroetch Testing Services

Also known as macroetch or metallographic testing, this process involves sectioning, polishing, and etching a welded sample to reveal its internal weld profile. Our team uses advanced equipment to inspect and document key weld attributes such as penetration depth, throat size, bead geometry, and fusion boundaries. These inspections are vital for PPAP submissions, early-stage design validation, and ongoing production quality control.

Equipment & Capabilities

ATACO’s lab is equipped with best-in-class metallographic tools, including:

- Buehler AbrasiMet® M abrasive saw for high-precision sectioning

- Buehler EcoMet® 30 dual-station polisher for mirror-finish surfaces

- Sentry Air Systems Winged Sentry fume hood for safe, consistent etching

- Dino-Lite EdgePLUS™ digital microscope and 4K monitor for detailed imaging

- ASNT Level II-certified visual inspector on staff

- Keyence VHX-X1 4K digital microscope for weld validation and reliable PPAP documentation

Our Cut & Etch Lab supports high-mix, low-volume and high-volume production, ensuring every weld is measured, documented, and certified according to your quality requirements.

Key Benefits

- Faster PPAP & First-Article Turnarounds

Receive cross-section weld images quickly without outsourcing delays.

- Quantifiable Weld Quality

Track weld performance across production runs, ideal for deep draw metal stamping, custom metal fabrication, and heavy-duty stamped parts.

- Integrated Quality & Fabrication

Pair our metallographic testing with robotic welding, 5-axis laser cutting, steel fabrication, and custom CNC machining all under one roof.

- Lower Cost of Quality

Reduce third-party testing fees and gain tighter control over weld quality.

Applications

Our weld quality assurance capabilities support industries where structural integrity is non-negotiable, such as:

- Off-highway construction equipment

- Agricultural implements

- Material handling systems

- Automotive and rail components

- Defense and sustainability products

For new part launches or ongoing validation of production welds, ATACO’s Cut & Etch Lab delivers the documented results your engineers and customers demand.

Request a Quote

Let’s talk about how in-house weld testing can improve your production timeline and part reliability. Request a quote today or contact us to schedule a Cut & Etch Lab demonstration.