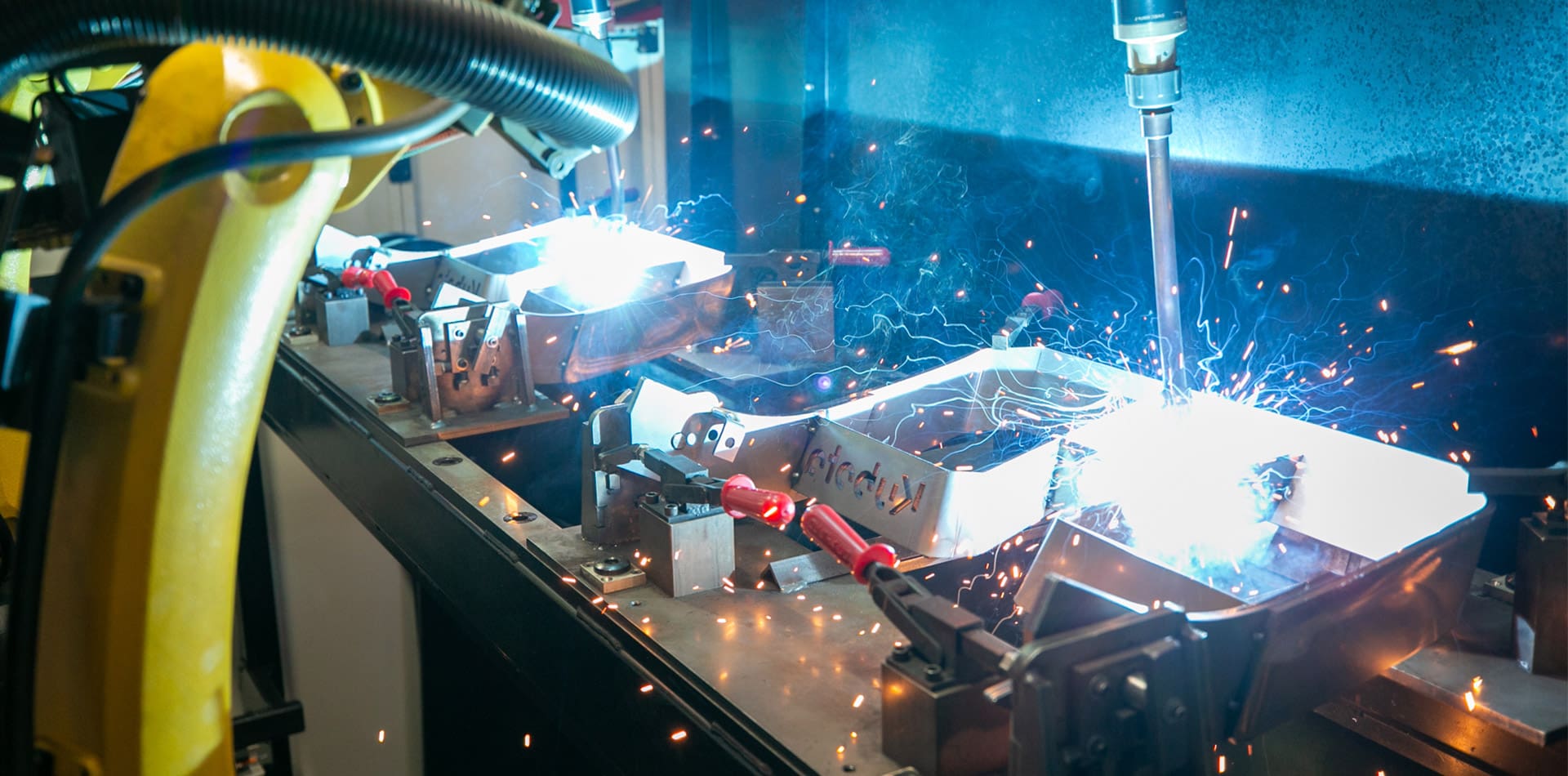

Welded Assemblies

ATACO Steel Products produces high-quality welded assemblies to meet the unique needs of our customers across many different industries. We utilize multiple robotic welders, pulse welders, resistance welders, and an array of MIG welding equipment ranging from 300 to 450 amps (see our full equipment list).

Manual Welding Capabilities

All our welding personnel are trained and tested in the classroom and must pass welding skills tests to become American Welding Society (AWS) certified. Our welders follow weld procedure specifications during production to ensure welded assemblies meet the requirements of both the customer and AWS. We can follow your company-written weld specifications or recommend a weld spec that suits your application.

Robotic Welding Services

ATACO’s robotic welding capabilities enable us to weld a wide range of parts quickly, efficiently, and with exceptional precision. Our robotic welding equipment uses seam tracking technology to take continuous readings throughout the process and adjust the weld path accordingly.

Seam tracking auto-corrects for any part variations, resulting in flawless welds placed precisely where they’re needed. Advanced MIG welding technology eliminates weld spatter, which is critical for parts with cosmetic surface considerations.

With two sides and an automatic welding positioner rotary table, a finished part can be removed and the next part fixtured as the welder is working autonomously on the other side.

Automated Part Positioning

ATACO utilizes advanced part manipulators to position parts for welding at the perfect angle. With our part manipulators, we can position our welds in flat or horizontal positions to avoid welding vertically whenever possible. More precise part positioning leads to better quality welds and better quality finished products.

The PerformArc positioning table operates on a high-speed servo, so the welder always knows where the parts are located. Position parameters are copied from one side to the other with much greater accuracy. This system has enabled ATACO to dramatically increase our productivity as the welding arc is always on, meaning your deliverable will be ready in less time and with even greater precision.

Welded Assemblies with Increased ROI

We deliver welded parts and assemblies with shorter production times, quicker turnarounds, and greater accuracy, increasing speed to market and ROI.

With headquarters in Cedarburg (near Milwaukee), ATACO Steel provides manual and automated welding services to customers across Wisconsin and beyond.

Request a quote on welded assemblies or contact ATACO to learn more.