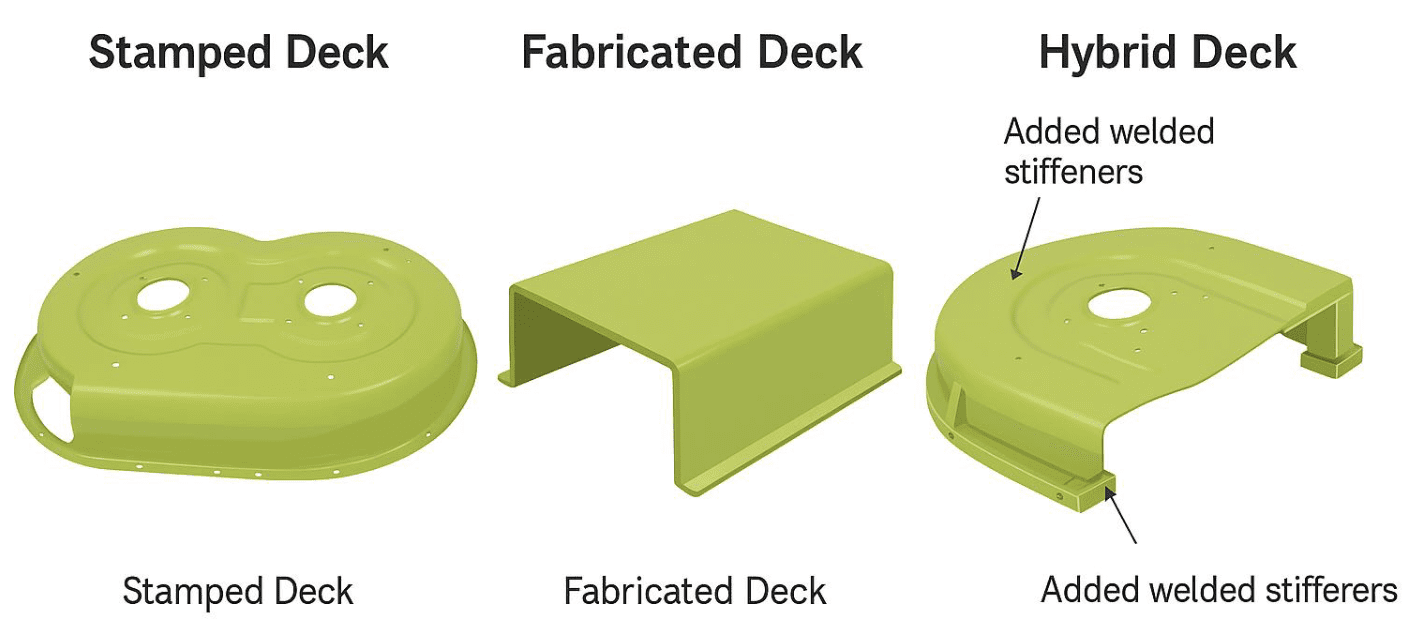

The construction method behind a mower deck plays a major role in cutting performance, product lifespan, and total cost. Original equipment manufacturers (OEMs) generally choose from three types of construction methods: deep draw metal stamping, full custom metal fabrication, or a hybrid approach that combines both. Each method serves different priorities, from airflow performance to structural strength and production cost.

The following breakdown helps identify which option aligns best with your performance targets, volume requirements, and margin goals. For OEMs looking to optimize for a specific customer base or product tier, understanding these differences is essential.

Key Attribute | Stamped Deck (Deep-Drawn) | Fabricated Deck | Hybrid Reinforced Deck (Stamped Shell + Fabricated Stiffeners) |

Manufacturing Method | One-pience deep draw stamping with high-tonnage presses | Multi-part sheet metal fabrication using CNC cutting and welding | Stamped shell, then welded or bolted reinforcement rings/baffles, thicker wear plates |

Air & Grass Flow | Smooth internal curves promote powerful suction and clean discharge | Angular geometry may cause turbulence and clogs | Maintains strong airflow when reinforcements are positioned to avoid flow disruption |

Structural Strength | Strength built into domes and contours; lightest weight | Rigid build, but highly dependent on weld quality | Best balance; reinforced edges and towers deliver targeted strength without excessive added weight |

Maintenance & Clean-Out | Fewer snag points, fewer seams: self-cleaning top & botto | More crevices and welds; heavier to life and rinse | External reinforcements allow smooth interior for faster clean-out |

Production Cost | Most cost-efficient at scale; minimal scrap | Highest due to cutting, welding, and finishing | Moderate; higher than stamped-only but lower than full fabrication |

Best Fit | Residential light-duty commercial applications, zero-turns focused on pristine finish | Rugged terrain, municipal contracts, commercial cutters | High-end zero-turns, large acreage tractors, premium residential models |

Deep‑Drawn Stamped Decks

Stamped decks begin as a single sheet of steel shaped into a deep, seamless bowl using deep draw metal stamping. A high-tonnage press pulls the material into its final form in one stroke, creating smooth curves that enhance airflow and minimize blockages. These built-in curves and domes also add rigidity, allowing thinner gauge material – typically 12 to 14 gauge – to perform like a thicker plate.

Stamped decks are ideal for high-volume applications requiring lightweight construction and precision-cut quality. Fewer welds and a self-cleaning shape make them a favorite for ease of maintenance.

Learn more about deep draw metal stamping.

Fully Fabricated Decks

Fabricated mower decks are assembled from flat steel sheets, often 7 to 10 gauge, cut by CNC laser or custom stamping. These pieces are formed and then welded into a box-like structure known for its rigidity. That strength comes at a cost: added weight, increased complexity, and more welds that require skilled labor and quality control.

Heavy commercial environments demand the durability that fabricated decks offer. However, the added bulk can affect fuel efficiency, mobility, and cleaning time. Success with fabricated builds depends heavily on weld consistency and fit-up accuracy.

See ATACO’s metal fabrication capabilities.

Hybrid Reinforced Decks

Hybrid mower decks combine a deep drawn shell with external fabricated reinforcements. Components like spindle collars, front lips, and skid plates are added using robotic welding or bolted assemblies. This method increases strength in targeted areas without compromising the interior dome that supports smooth airflow.

Many OEMs adopt hybrid decks to strike a balance between lightweight construction and commercial-grade toughness. Weight savings typically range from 15 to 25 pounds compared to fully fabricated alternatives, helping improve maneuverability and deck lift responsiveness. Reinforcements are placed externally to keep the airflow channel clear and maintain the signature suction associated with stamped decks.

Explore our hybrid manufacturing solutions.

Frequently Asked Questions

What is a hybrid mower deck?

A hybrid mower deck consists of a deep drawn metal stamping shell paired with external steel fabrications to fortify high-impact areas. This approach combines airflow efficiency with added durability.

How does the cost compare to a stamped-only deck?

Expect a 10–15% premium over basic stamped construction. It remains more cost-effective than a fully fabricated build.

Can a hybrid deck deliver equal cut quality to a stamped deck?

Yes. Reinforcements are engineered to avoid obstructing the airflow path, so the hybrid retains the lift and clean discharge pattern associated with stamped designs.

Does ATACO manufacture hybrid mower decks?

Yes. ATACO Steel Products offers full support for hybrid deck programs. Our capabilities include deep draw metal stamping, multi‑axis laser cutting, robotic welding, and metal forming simulation software, all under one roof.

Ready to Start Your Next Deck Program?

ATACO Steel Products Corp works alongside OEMs to develop mower deck programs that balance performance, durability, and cost. From custom metal fabrication to high-volume metal stamping, we provide the technology, experience, and engineering support to help manufacturers compete. Request a quote today.