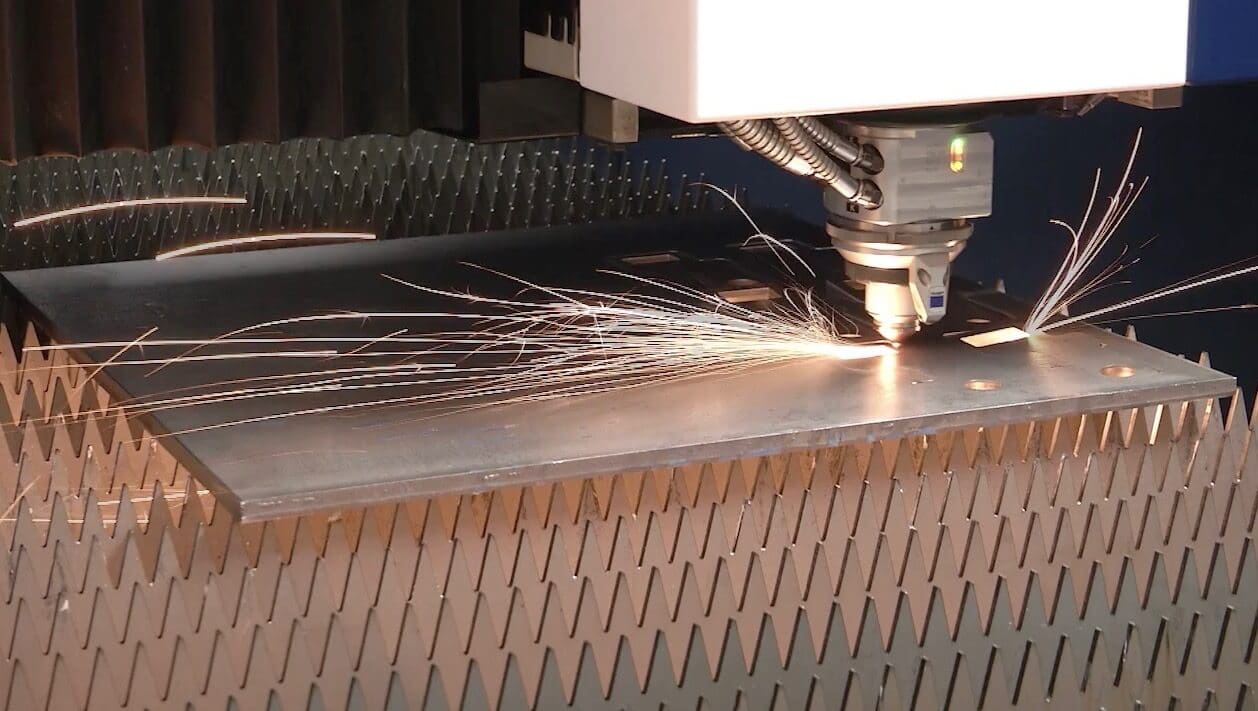

At ATACO Steel Products, our aim is to be technically advanced and strategic in our investment decisions. Our recent purchase of a TRUMPF 5030 12kW laser aligns with our vision and values.

We’re pleased to announce that we’re already prepping the area where this new 12k watt laser will be producing parts upon delivery in March 2021. Learn more about the benefits of our TRUMPF 5030 TruLaser below, or contact us for a free quote:

Faster Laser Cutting – without Cutting Corners

With its high processing speed and reproducible part quality, the TRUMPF TruLaser 5030 fiber handles even complex contours with relative ease. Solid state 12kW laser power ensures our ability to achieve excellent feed rates and cutting speeds including the capability to cut mild steel up to 30 mm thick and standard sheet sizes of 3000 mm x 1500 mm with a max weight of 1800 kg for one pallet. Not limited to steel, the TruLaser 5030 fiber also cuts stainless steel, aluminum, copper, brass, titanium, and nickel.

This powerhouse features perfect nozzle quality (even when fully automatic), and the ability to monitor important machine elements that could affect cutting ability. High speed laser cutting capability is underscored by reduced non-productive time, thanks to the automatic nozzle changer and automatic beam centering.

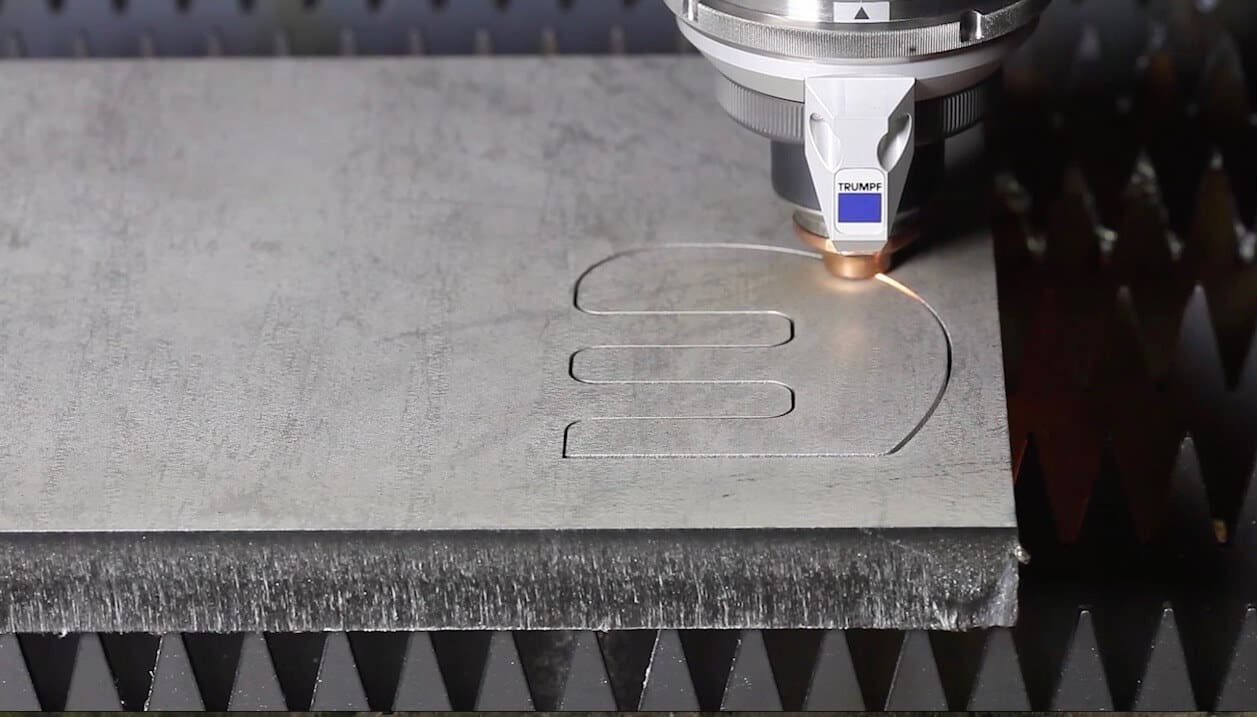

Highspeed Eco Cutting Process & Other Advantages

TRUMPF’s Highspeed Eco feature delivers up to 100% higher productivity with less gas consumption. This productive machine handles thick and thin sheet metal effortlessly, in the best possible quality, even with fully automated operation.

Additional benefits include:

- Minimal part costs. Due to powerful drives and dynamic axis motions, it has high machine dynamics even for complex contours.

- DetectLine built-in camera system enables rework of already-cut parts with absolute precision.

- Newly-designed nozzle reduces nitrogen consumption by 70% for double the sheet throughput.

- Smart nozzle inspection and the intelligent LensLine function ensure high nozzle and lens quality, even in fully automatic operation.

- Intuitive operation with multi-award-winning Touchpoint HMI means faster production without sacrificing performance.

- Laser quickly and easily cuts oversized sheets up to 6 x 2 m.

- CoolLine function cuts intricate contours in thick mild steel. Benefits include new geometries, closer nesting and increased reliability processing thick mild steel.

- BrightLine fiber achieves extremely smooth cutting edges for excellent part quality and seamless removal.

- AdjustLine enables our operators to adjust the cutting process to materials of different quality. This means cost-savings for our customers through reduced scrap and lower material costs.

- Collision protection for the cutting head guarantees the highest process reliability.

These innovations, along with our expertise and ISO-certified processes, allow ATACO Steel to offer the highest-quality cut metal parts with faster turnaround and more competitive pricing.

Does Your Project Require High Speed Metal Laser Cutting?

Located near Milwaukee in Cedarburg, Wisconsin, ATACO Steel Products is a leader in the sheet metal fabrication industry. Learn more about our metal laser cutting services and when to consider 2D laser cutting for your project.

By upgrading to the latest manufacturing methods, we continue to ensure customer satisfaction in every project. In addition to purchasing the TRUMPF 5030 12kW Laser, we will also be taking delivery of a new TRUMPF 5130 series 130-ton press brake, next month. We’ve been customer-focused since 1946 with repeat business our constant goal.

Reach out today to learn more about how ATACO Steel Products can exceed your expectations. We’re committed to providing quality parts on time and on budget.

Request a quote for high speed laser cutting or contact ATACO Steel for more information.