Sheet Metal Fabrication for Construction Equipment

ATACO Steel Products is one of the premier custom steel fabricators supplying the construction equipment market. Industry-leading OEMs the world over turn to ATACO for the fabricated metal parts, steel metal stamping parts and deep drawn components such as deep drawn shells and

reservoirs that their hardworking equipment needs.

Construction equipment OEMs face a variety of challenges including seasonality, stringent weld specs and quality dependencies between metal parts. ATACO has the manufacturing capabilities to produce nearly any metal part your project calls for, including comprehensive fabrication services, secondary forming and finishing processes, letting our clients source multiple manufacturing needs from a single vendor. Whether you’re looking to outsource a simple part or a complex subassembly with multiple components, ATACO’s services can help simplify your supply base and coordinate with the rate of your production lines.

Construction Equipment Parts Manufacturing

The construction equipment manufacturing OEMs we serve demand accuracy, quality and reliable performance for every part and fabrication we produce. ATACO meets or exceeds expectations for all manufactured construction equipment parts, delivering them on time with exceptional precision.

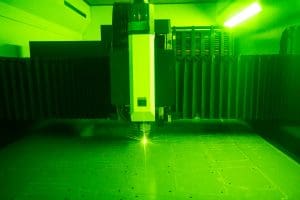

Our robust manufacturing capabilities include processes and equipment unique to the construction equipment industry. Full service custom fabrication, 5-axis laser cutting systems, and more enable us to produce parts and components that match our customers’ exact designs. Our skilled production team includes an AWS certified weld instructor to create weldments with perfect precision. We specialize in deep draw stamping and can manufacture complex deep drawn metal stampings up to 16” in depth of draw.

ATACO Steel Products has an in-house tool and die room which ensures all our hardware satisfies both design specifications and our own quality standards. Manufacturing our own tooling and stamping dies also eliminates any potential delays involved with outsourcing.

Metal Stamped Construction Equipment Parts

Examples of the quality, custom stamped metal parts we manufacture for construction equipment include:

- Brackets

- Electrical housings

- Fuel/oil/heater tanks

- Grease/coolant reservoir tanks

- Tank straps

- Frames

- Enclosures

- Heat shields

- Toggle switch guards

- Muffler clamps

- Rain caps

- Core plugs

- Standoff parts

- Loader arms

- Exhaust stacks

- Cooling tower parts

We specialize in complex products and have the proven ability to produce even the most complicated construction equipment parts with tight tolerances and perfect repeatability. Construction equipment we manufacture parts for includes excavators, backhoes, bulldozers, loaders, graders, pavers, compactors, cranes and many other types of heavy equipment.

Material Selection for Heavy Equipment Parts

Stamped parts used in construction equipment must be able to perform in harsh environments, withstanding rigorous use and temperature fluctuations while resisting corrosion. In addition to part design, material selection is also key when high strength and durability are required.

Materials commonly used for heavy equipment parts include aluminum alloys and different stainless steels. As a heavy equipment parts manufacturer we work with carbon steel, stainless steel, aluminum and other high-strength materials including many different alloys.

Each heavy equipment fabrication project will have its own unique specifications, and choosing the right metal alloy is a critical step. ATACO engineers can help you with material selection as well as product design for manufacturability. Our engineering team has expert knowledge of how different metal materials respond to pressure and force, and knows how to apply this knowledge to create safe and cost-effective parts manufacturing solutions for our clients in the heavy equipment industry.

Exacting Precision in Heavy Duty Metal Fabrication

Construction equipment may be heavy-duty but it still requires the utmost precision in manufacturing every component. ATACO’s production team works with top-of-the line equipment in all manufacturing processes, and we continually upgrade our equipment to stay at the leading edge of technology.

Our quality controls are ISO 9001:2015 certified, and quality management is involved from initial project planning all the way through final approval. ATACO’s commitment to investing in cutting-edge technology isn’t limited to production. Our quality inspection tools, equipment and processes are also subject to continuous improvement.

Request a Quote

for Custom Construction Equipment Parts

ATACO Steel offers flexible scheduling and fast turnaround times to deliver the custom fabricated or stamped parts you need in time to meet your production deadlines. This attention to strictly meeting production schedules has made us a leader among custom steel fabricators for decades.

Request a quote today for the precision fabricated components and stamped parts you need, or contact ATACO Steel Products with questions.