Deep Draw Stamping & Fabrication for Powersports Equipment

ATACO Steel Products manufactures deep drawn stampings, fabricated components, and welded assemblies for powersports OEMs. We support Sport and Recreation Vehicle (SRV) platforms, including UTVs and side-by-side equipment used in off-road applications.

Our customers rely on ATACO for parts that fit, assemble consistently, and hold up in demanding operation conditions. From early production builds through long-running programs, we supply repeatable metal components from our U.S. manufacturing facility.

Built for Off-Road Use

Powersports equipment is exposed to vibration, moisture, dirt, and temperature changes. Parts must be strong, properly formed, and consistent from run to run.

ATACO uses heavy-tonnage stamping presses, precision fabrication equipment, and in-house tooling support to produce components that meet OEM requirements for strength and rigidity. Our process helps maintain part-to-part consistency as production volumes increase.

Powersports Parts and Subassemblies

Products:

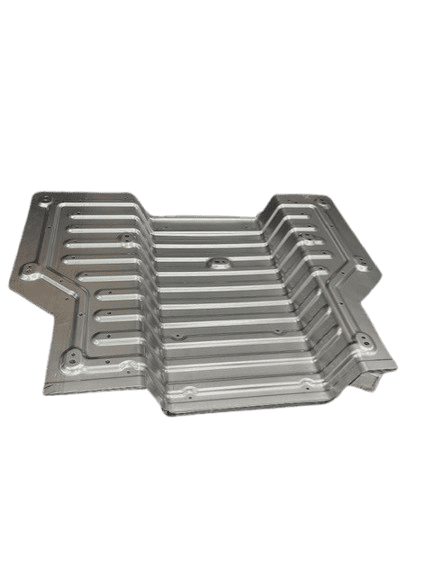

- Deep drawn panels and shells for vehicle structures

- Structural brackets and mounting components

- Battery trays and electrical housings

- Guards, shields, and protective covers

- Welded subassemblies combining stamped and fabricated parts

- Reinforcement features and formed stiffeners

Material Options and Manufacturing Support

ATACO works with carbon steel, stainless steel, and other common materials used in SRV and UTV platforms. Material selection is driven by strength, corrosion resistance, and cost requirements.

Our team supports manufacturability reviews to help stabilize designs and avoid issues as programs move into production.